DTG vs DTF Printing Explained: Key Differences and Applications

- Stitch 99

- Dec 30, 2025

- 4 min read

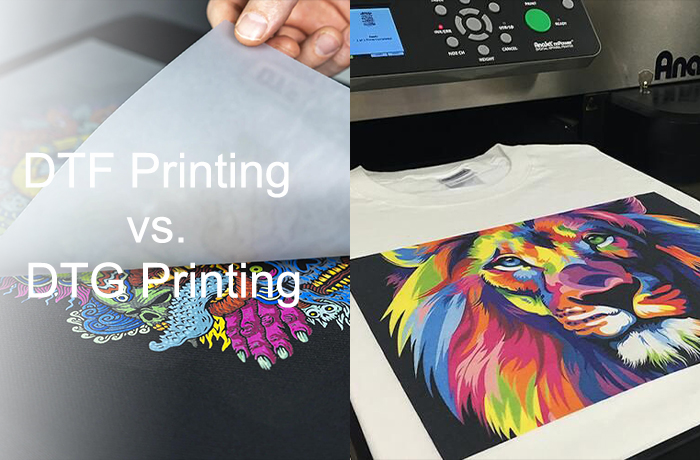

Direct to Garment (DTG) and Direct to Film (DTF) are two popular printing methods for custom apparel, each with distinct advantages. DTG printing offers high detail and soft prints directly onto garments, while DTF printing provides strong adhesion on a wider range of materials and is better suited for bulk orders. Understanding these differences helps in selecting the right technique based on fabric type, print durability, and production speed. Stitch 99 offers both DTG and DTF printing solutions to meet diverse customer needs.

DTG works best for smaller runs and intricate, full-colour designs on cotton fabrics. DTF printing uses a transfer film that allows printing on various fabrics, including polyester, making it more versatile for mixed textiles. Both methods have unique benefits, so knowing their core features assists in making an informed choice.

Key Takeaways

DTG excels in detailed prints on cotton with a soft feel.

DTF printing is versatile across different fabrics and suitable for larger runs.

Choosing the right method depends on fabric type and order size.

Comparing DTG and DTF Printing Methods

Both DTG and DTF printing offer distinct advantages in print quality, equipment requirements, material handling, and colour performance. These factors determine the best method depending on project needs. Stitch 99 provides expert guidance on choosing between DTG and DTF printing for your specific requirements.

Print Quality and Detail

DTG printing excels in producing detailed and smooth gradients directly on garments. It uses water-based inks applied directly to textiles, allowing fine lines and photographic clarity, especially on cotton.

DTF printing, meanwhile, prints designs on film before heat-transferring them to fabric. It can achieve sharp details and solid fills but sometimes struggles with very fine gradients compared to DTG.

DTG generally offers better softness in prints, as ink soaks into fibres rather than sitting on top. DTF prints have a slight texture due to the adhesive layer but provide consistent coverage on multi-fabric colours.

Equipment and Printing Process

DTG printers require pre-treatment of garments, especially dark fabrics, to improve ink adhesion and vibrancy. This adds steps and specialised equipment like pretreatment machines and curing ovens.

DTF printing setups include a printer for the transfer film, a powder applicator, and a curing system to fix the adhesive powder. The process involves printing, powdering, curing, then heat-pressing to the fabric.

DTF machines tend to have a simpler preparation process on the garment itself but involve additional equipment for handling films and powders. DTG setups centre more on direct fabric preparation and ink maintenance.

Material Compatibility

DTG printing works best on natural fibres, primarily cotton, as water-based inks bond well here. Synthetic fabrics often require specialised primers or treatments which can complicate the process.

DTF printing is highly versatile, able to print on cotton, polyester, nylon, blends, and even leather. The transfer process allows for consistent application across diverse surfaces without pre-treatment.

This flexibility makes DTF printing preferable for brands needing to print on various fabric types without changing inks or settings extensively. Stitch 99 frequently recommends DTF printing for clients with diverse material needs.

Colour Vibrancy and Durability

DTG prints offer vibrant colours on light-coloured garments but can fade faster when exposed to harsh washing or sunlight. Pre-treatment and curing quality impact the durability significantly.

DTF printing tends to maintain bright, saturated colours even on dark garments, thanks to the adhesive layer locking ink in place. The transfer film can protect ink from cracking and washing out.

Both methods require proper post-print handling for best longevity, but DTF printing generally provides more robust colour retention in varied conditions.

Choosing Between DTG and DTF for Your Needs

Selecting between DTG and DTF printing involves evaluating costs, production capacity, and environmental considerations. Stitch 99 helps customers make informed decisions on the best printing method for their apparel projects.

Cost Considerations

DTG printing typically requires a higher initial investment due to specialised printers and pretreatment equipment. However, it is cost-effective for short runs and complex, multi-colour designs because it prints directly onto garments with minimal setup.

DTF printing generally has lower equipment costs and uses heat transfer films, which can be cheaper at higher volumes. The cost per print decreases with larger batches, making DTF printing more economical for bulk orders.

Material costs also vary: DTG uses specific textile-friendly inks, while DTF printing ink costs are usually lower, but additional powder adhesive adds to expenses. Choosing between them depends on order size and budget flexibility.

Production Speed and Scalability

DTF printing allows faster production speeds. Transfers can be prepared in bulk, stored, and applied on demand, enabling efficient scaling for large orders without slowing printing throughput.

DTG is slower, as each garment must be printed individually and pretreated. This limits its scalability, especially for high-volume demands, though it is ideal for custom, one-off pieces or small batches.

Businesses aiming for rapid turnaround or high-volume orders may prefer DTF printing for its versatility and efficiency. DTG suits those prioritising print detail and individual customisation despite longer print times. Stitch 99 can help determine which printing method fits your business goals.

For more guidance, explore our blogs “DTF Printing Near Me” and “Best DTF Printer UK” to deepen your understanding of equipment and service options.

Environmental Impact

DTG printing typically uses water-based inks, which are more environmentally friendly and generate less waste. Its direct application reduces material consumption since no additional transfer films are needed.

DTF printing, used by Stitch 99, involves plastic transfer films and adhesive powders, generating more waste and using more energy in the curing process. These factors can increase its environmental footprint. However, Stitch 99 emphasizes that responsible recycling and disposal practices can help address some environmental concerns associated with DTF printing. Stitch 99 continues to explore ways to make DTF printing more sustainable for their customers.

Comments